Sorry I just answerd in detail all points but I must have timed out again so fuck it...I'll get into it again when I feel like it right now this system just pissed me off.

Just to quickly answer without going into the nitty gritty details of materials and components etc...,

a) it was not speculation to what is patentable, it was a clear statement that the overall layout is public knowledge and it is the dimensions, arrangement of sensors and other components used that are proprietary to Kawasaki and are at the heart of the patents. The blower itself is not patented as it follows other, new but conventional blower designs and it is still not clear if it actually is a Kawasaki only make. Bottom line, the R version components can easily be reproduced...

b) If you think that tuning at this level, meaning 300+HP, is or could be a run of the mill mass production you are living in a different dimension. This kind of tuning is always "one of a kind job" (meaning it is always specific components adapted to one particular ride, a hand made job everytime) and it comes at a related cost. Kawasaki is the first to "mass" produce such a machine and it is certainly not for the profits, it is to put them back to the top of the engine race..as simple as that.

c) As for buyer's philosophy, most of those buying the H2R do so for the prestige and to race it on a track. On the other hand a great many of those buying the H2 will do so with the intention to upgrade it to the 300HP of the R and even more because they see it as a good (already legal) platform to do so. If I were in the position I was not to long ago that is what I would do, at lesser cost then what other options represent. But that is why I pumped my R1 to 325HP while you are content with a near stock ZX, not that it is a bad thing, just a different philosophy.

Take the example of my friend at Stylmoto, he has a ZX14 with 1720cc pumping out 450HP (measured at the rear wheel). He used components CNC machined from bulk Carbon and Titanium, net-shape-spray-formed Titanium-aluminide...everything coated with materials from Molibdenum-disilicide to beta-phased Calcium phosphate...at these levels the advantage of high volume production disappears because the cost of materials greatly outweighs the cost of manufacturing. I would feel safer as test pilot of my friend's virgin ride then on the first H2R test ride.

..just because of the custom materials tailored to each specific component, something an OEM cannot afford to do.

P.S. I wonder why so many patents are challenged and lost and why so many court cases drag on for years if the patent process is as clean and clear cut as you make it sound...

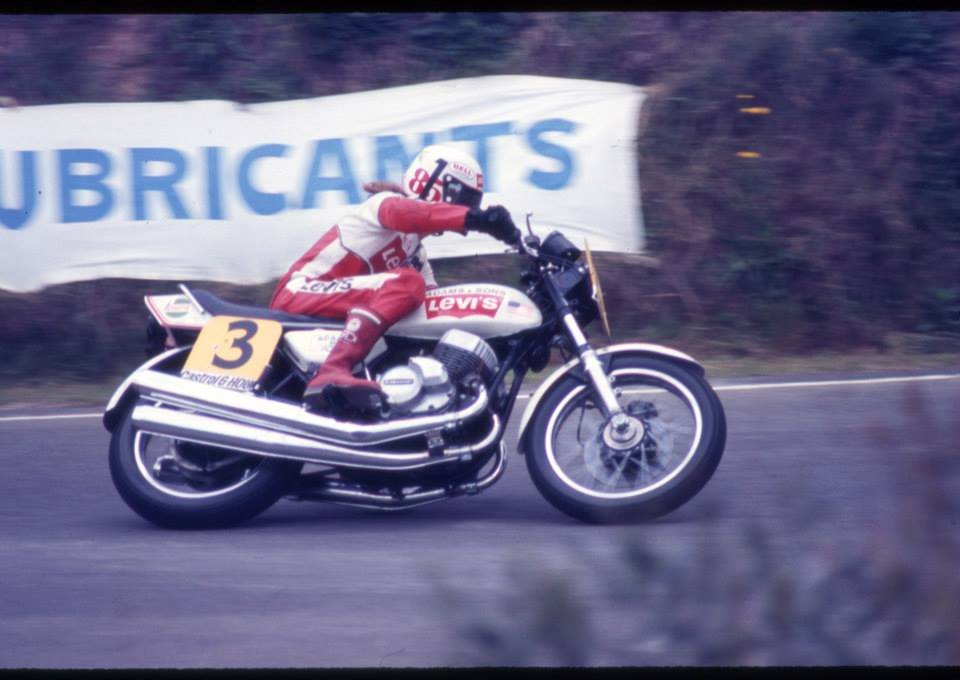

memories memories...

memories memories...